The Department of Metallurgical Engineering serves as a leading center for metallurgical education, research, and industry collaboration. We are dedicated to cultivating a dynamic learning environment that fosters innovation, analytical thinking, and technical proficiency, empowering our students to become future leaders in metallurgy and materials engineering.

At OP Jindal University, our Metallurgical Engineering program is designed to meet the dynamic needs of the steel and materials industry. We provide our students with a strong foundation in physical metallurgy, extractive metallurgy, process metallurgy and mechanical metallurgy while integrating the latest advancements in computational materials engineering, additive manufacturing, and sustainable metallurgical practices. Our curriculum is aligned with the National Education Policy (NEP 2020), offering a multidisciplinary approach, skill-based learning, and industry-oriented training.

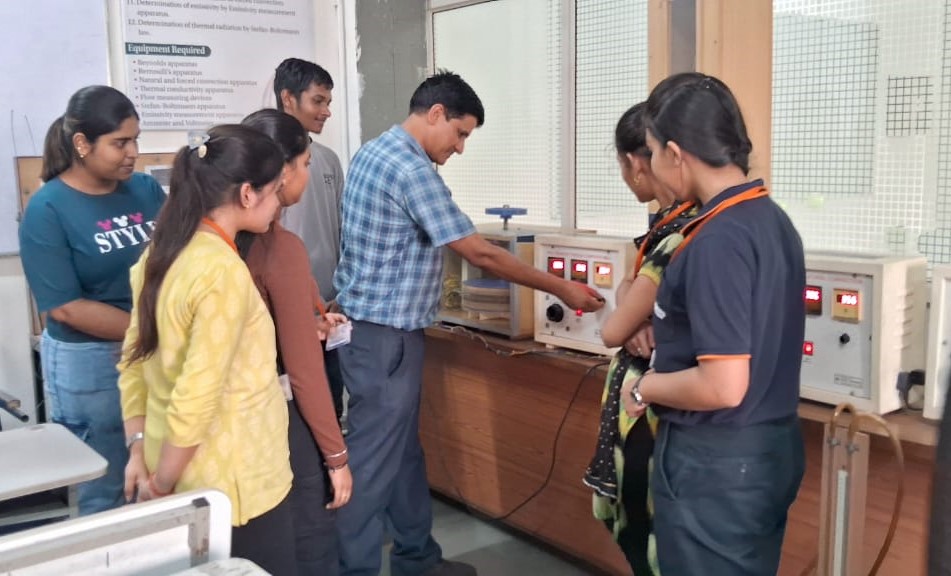

One of the key strengths of our department is our dedicated faculty members, who are actively involved in cutting-edge research and industrial consultancy. Our research contributions span various domains, including high-performance alloys, rail steels, superalloys, non-ferrous alloys, corrosion engineering, and solid waste utilization in metallurgical processes, composite materials, computational metallurgy, additive manufacturing. With a strong emphasis on experiential learning, we provide our students access to state-of-the-art laboratories, including the Center of Excellence in Steel Technology (CoEST) enabling hands-on experience with advanced characterization techniques such as SEM, EDX, XRD and many more.

Innovation and entrepreneurship are at the heart of our initiatives. Through our collaborations with industry leaders, research organizations, and academic institutions globally, we have fostered an ecosystem that promotes innovation-driven research. Our students and faculty members have been actively involved in patent filings and grants, funded projects, and technology development, significantly contributing to the metallurgical and materials sector.

The Metallurgical Engineering Department at OPJU also takes immense pride in its strong industry linkages, which provide our students with valuable internship and placement opportunities. We collaborate with leading organizations in steel, mining, and manufacturing sectors, ensuring that our graduates are industry-ready and equipped with the latest technological advancements and problem-solving skills. Additionally, we actively engage in faculty development programs, industrial training sessions, and international collaborations to ensure continuous knowledge enhancement and skill development.

As we move forward, our vision remains clear: to position the Department of Metallurgical Engineering at OPJU as a premier center for education, research, and industrial engagement. We aim to contribute to national and global advancements in metallurgical and materials engineering while fostering sustainable and innovative solutions for industry and society.

I invite all the aspiring metallurgical and materials engineers, researchers, and industry professionals to join us in our journey towards academic and research excellence. Let us work together to shape the future of metallurgy and materials engineering for a sustainable and technologically advanced world.

.jpg)

-(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Social Media Link